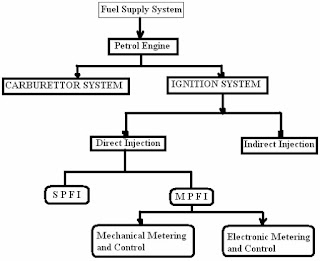

Introduction: The fuel system of an Internal Combustion engine is intended to produce a combustibl mixture composed of the fuel stored in the fuel tank and the atmospheric air, and then deliver both to the cylinders. Petrol engines use light grade gasoline.

Components of fuel feed system:

The fuel feed system of a petrol engine are having the following components.

1. Fuel Tank

2. Fuel Pump

3. Fuel Filter

4. Carburetor

5. Intake manifold

6. Fuel lines

7. Fuel Gauge

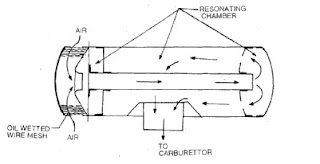

Oil Bath Type Air Cleaner

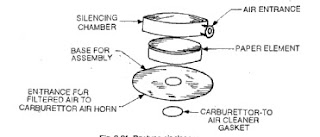

Dry Type Air Cleaner

Centrifugal Type air cleaner

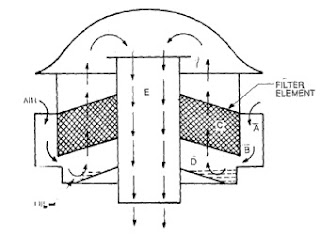

OIL BATH TYPE AIR CLEANER

Types of Fuel Feed Systems: The fuel from the fuel tank can be supplied to the engine cylinder by the following systems.

1. Gravity System.

2. Pressure system

3. Vacuum System

4. Pump System

5. Fuel Injection System.

Functions of fuel feed system:

1. To store the fuel in the fuel tank.

2. To supply fuel to the engine to the required amount and in proper conditions.

3. To indicate o the driver the fuel level in the fuel tank.

In the gravity fuel feed system, the fuel tank is mounted at a place higher than that of the carburetor. The fuel flows from the tank to the carburetor due to the gravitational force. Thus the system does not require

any fuel pump. The fuel tank is directly connected to the carburetor. Scooters and motorcycles use this system.

In pressure system, a pressure sealed tank is used. The pressure is created in the tank by means of a separate pump. For starting, the pump is primed by cam which produces pressure in the tank and fuel flows to the carburetor. In this system the tank can be placed above or below the carburetor.

In vacuum system, the engine suction is used for sucking the fuel from the main tank to the auxiliary fuel tank from where it flows by gravity to the carburetor.

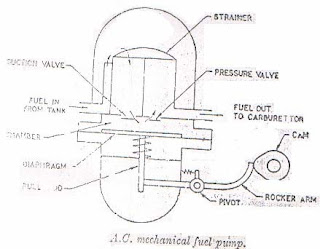

In pump system, a fuel pump is used to feed the fuel from the fuel tank to the carburetor. The pump is driven either by the cam shaft or electrically. In this system, the fuel tank can be placed at any suitable position in the vehicle.

In the fuel injection system, a fuel injection pump is used in place of carburetor. The fuel is atomized by means of a nozzle and then delivered into an air stream. Separate fuel injection system is used for each cylinder which controls the mixture under different load and speed conditions.

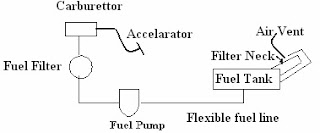

Fuel Tank: The fuel tank is made of sheet metal. It is usually attached to the frame at a rear of vehicle. Its capacity ranges from 70 to 120 liters. The filler neck of the tank is closed by a cap. In some other tanks, there is a filtering element at the fuel line connection to convert dirt and prevent it from reaching to the pump and carburetor. A drain plug is provided at the bottom for emptying the tank. The tank also contains the float unit of the fuel gauge. It may also have a vent pipe which allows air to escape when the tank is being filled. In the cars, that are equipped with vapor recovering system, thevent pipe is connected to condenser which contains the vaporized gasoline in the tank and prevents its escape into the air.

Fuel line: The copper or steel tubes and hoses are used for connecting fuel tank with pump with carburetor. The tube connecting the fuel tank and pump is fastened rigidly to the frame or body. The first and last portion

generally consists of a flexible tube that joints the rigid line to the fuel tank or to the pump. This allows the fuel tank to oscillate with the body and the pump with the engine without breaking or loosening the line.

Fuel Filters: The fuel is filtered at different stages in a fuel supply system. Therefore, many fuel filters are used in the fuel circuit. The fuel filter serves the purpose of filtration in the fuel delivery system by preventing foreign particles from entering into the fuel pump and the carburetor. The modern filtration practice employs a combination of coarse and fine filters.

Course filters are incorporated within the fuel tank.

Medium coarse filter are outside the fuel tank and on the inlet side of the pump.

Fine filters of built in surface type at inlet of fuel pumps pumping chamber.

Fine filter in pipe line is between fuel pump and the carburetor.

Fuel pumps: A fuel pump is used to deliver fuel from the fuel tank to the float chamber of carburetor. Main types of fuel pumps commonly used on auto vehicles.

1. A.C. Mechanical pump

2. S.U. Electrical pump

3. Electromagnet pump

4. Combined pump (fuel pump with a vacuum

pump)