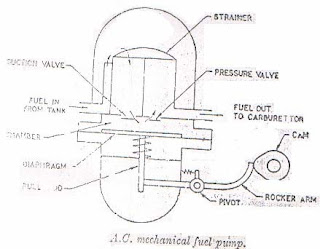

Mechanical Pump: The mechanically operated diaphragm type fuel pump is operated by an eccentric mounted on the camshaft of the engine. The pump consists of a spring loaded flexible diaphragm actuated by a rocker arm. The rocker arm is actuated by the eccentric. Spring loaded valves are there in the inlet and outlet of the pump. These valves ensure flow of fuel in the proper direction.

As the rocker arm is moved by the eccentric, the diaphragm is pulled down against the spring force. This movement causes a partial vacuum in the pump chamber. Now the delivery valve remains closed and the suction valve opens. This admits fuel into the pump chamber. At the maximum position of the eccentric, the diaphragm is flexed to the maximum extent after this further rotation of the eccentric will release the rocker arm. Now the rocker arm will simply follow eccentric by the action of the return spring. The

diaphragm spring will now push the diaphragm upwards and the force the fuel to flow out, opening the delivery valve, into the delivery tube. Now the suction valve remains closed.

In this pump, the downward movement is caused by the rocker arm, while the delivery stroke is achieved by the force of the diaphragm spring The diaphragm spring is so designed that the fuel pressure is suitable balanced by the buoyancy of the float system of the carburetor. As such, when deliver fuel to the carburetor. In this case, the rocker arm simply continues to rock while the diaphragm remains at or near its lowest travel. However, as the carburetor uses fuel, the needle valve opens to admit fuelinto the float bowl. Now the diaphragm moves downward by the rocker action and sucks the fuel to deliver back the same when required. This self regulating feature helps the pump to deliver the correct quantity of fuel at all operating conditions.

No comments:

Post a Comment